Product Introduction

Grade 317L stainless steel:

Alloy 317L (UNS S31703) is a molybdenum-bearing austenitic stainless steel with greatly increased resistance to chemical attack as compared to the conventional chromium-nickel austenitic stainless steels such as Alloy 304. In addition, Alloy 317L offers higher creep, stress-to-rupture, and tensile strength at elevated temperatures than conventional stainless steels. It is a low carbon or "L" grade which provides resistance to sensitization during welding and other thermal processes.

General Properties

Alloy 317L (UNS S31703) is a lowcarbon corrosion resistant austenitic chromium-nickel-molybdenum stainless steel. The high levels of these elements assure the alloy has superior chloride pitting and general corrosion resistance to the conventional 304/304L and 316/316L grades. The alloy provides improved resistance relative to 316L in strongly corrosive environments containing sulfurous media, chlorides, and other halides.

The low carbon content of Alloy 317L enables it to be welded without intergranular corrosion resulting from chromium carbide precipitation enabling it to be used in the as-welded condition. With the addition of nitrogen as a strengthening agent, the alloy can be dual certified as Alloy 317 (UNS S31700).

Alloy 317L is non-magnetic in the annealed condition. It cannot be hardened by heat treatment, however the material will harden due to cold working. Alloy 317L can be easily welded and processed by standard shop fabrication practices.

Програми

Air Pollution Control — flue gas desulfurization systems (FGD)

Chemical and Petrochemical Processing

Explosives

Food and Beverage Processing

Petroleum Refining

Power Generation — condensers

Pulp and Paper

Chemical properties(wt%)

Сорт | С | Mn | Сі | П | S | Кр | Ні | |

317L | хв. | - | - | - | - | 18.00 | 11.00 | |

max. | 0.03 | 2.00 | 1.00 | 0.045 | 0.03 | 20.00 | 15.00 | |

Механічні властивості

The typical mechanical properties of grade 317L stainless steels are listed in the following table

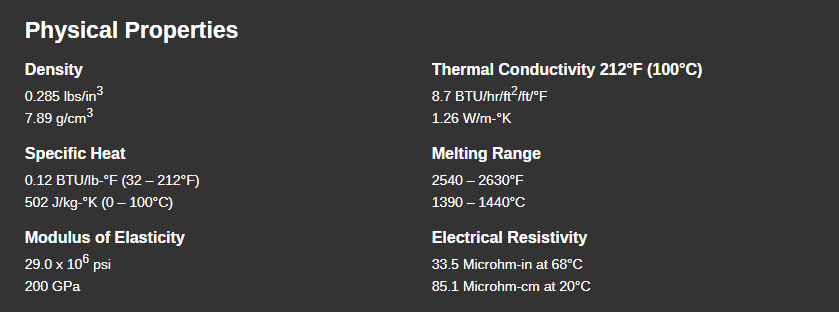

Фізичні властивості

The typical Physical properties of grade 317L stainless steels are listed in the following table:

Corrosion Resistance:

The higher molybdenum content of Alloy 317L assures superior general and localized corrosion resistance in most media when compared with 304/304L and 316/316L stainless steels. Environments that don't attack 304/304L stainless steel will normally not corrode 317L. One exception, however, are strongly oxidizing acids such as nitric acid. Alloys that contain molybdenum generally do not perform as well in these environments.

Alloy 317L has excellent corrosion resistance to a wide range of chemicals. It resists attack in sulfuric acid, acidic chlorine and phosphoric acid. It is used in handling hot organic and fatty acids often present in food and pharmaceutical processing applications.

The corrosion resistance of 317 and 317L should be the same in any given environment. The one exception is where the alloy will be exposed to temperatures in the chromium carbide precipitation range of 800 – 1500°F (427 – 816°C). Because of its low carbon content, 317L is the preferred material in this service to guard against intergranular corrosion.

Cold Forming

The alloy is quite ductile and forms easily. The addition of molybdenum and nitrogen implies more powerful processing equipment may be necessary when compared with the standard 304/304L grades.

Hot Forming

Working temperatures of 1652 – 2102°F (900 – 1150°C) are recommended for hot working processes. Do not work this alloy below 1742°F (950°C). If the final forming temperature falls below this threshold, a solution anneal of 1976 – 2156°F (1080 – 1180°C) is necessary. Rapid quenching is required.

Механічна обробка

The cold work hardening rate of Alloy 317L makes it less machinable than 410 stainless steel. The table below provides relevant machining data.